Innovate Motorsport’s SCG-1 Boost Controller Wideband gauge gives you complete control over boost levels with security of an Air/Fuel-based boost cut. We install one on a turbocharged F-Body Camaro.

Making big power has gotten easier as technology has evolved. The advances in turbochargers, boost controllers, and fuel delivery over the past 20 years have made once unheard of power levels achievable to nearly anyone. As the performance envelope has been pushed, the importance of, and need for precise data has grown exponentially.

nnovate Motorsports is on the forefront of data acquisition and driver interface. The company’s line of PowerSafe gauges are the perfect blend of precise data delivery and highly-engineered safety features. One of these gauges is Innovate’s SCG-1—a high-quality wideband air/fuel ratio gauge with an intelligent boost controller. It’s equiped with a boost safety override and shift light.

The gauge features a Bosch LSU 4.9 wide band sensor. This gives the user the most exact air/fuel ratios available. The included solenoid allows the user to control boost levels right in the gauge. If the wideband sensor reads below a user-defined A/F ratio, it is designed to temporarily disable the factory or aftermarket boost controller, leaving just the wastegate spring to control boost. The rapid reduction in boost based on the air/fuel ratio can be the different between a minor issue and a destroyed engine.

Installation

Installation of the gauge is fairly straightforward and includes everything needed to wire and plumb the system. For our installation, we teamed up with Colt Mills who owns a single turbo 2001 Camaro SS. The turbo kit is a new addition for Mills and he was looking to monitor boost, air/fuel ratio, as well as add a boost controller. The safety features of the SCG-1 were also a welcomed bonus.

Mills started by deciding on a location for the wideband sensor. The kit includes a Bosch LSU 4.9 sensor and a 1-inch bung. The bung is designed to keep the sensor just out of the main flow of exhaust. The placement in the pipe is also critical. If it is too close to the exhaust outlet, false-lean readings may occur. The sensor should also be located between 9 o’clock and 3 o’clock to prevent moisture from condensation from settling in the sensor. This moisture can damage the sensor.

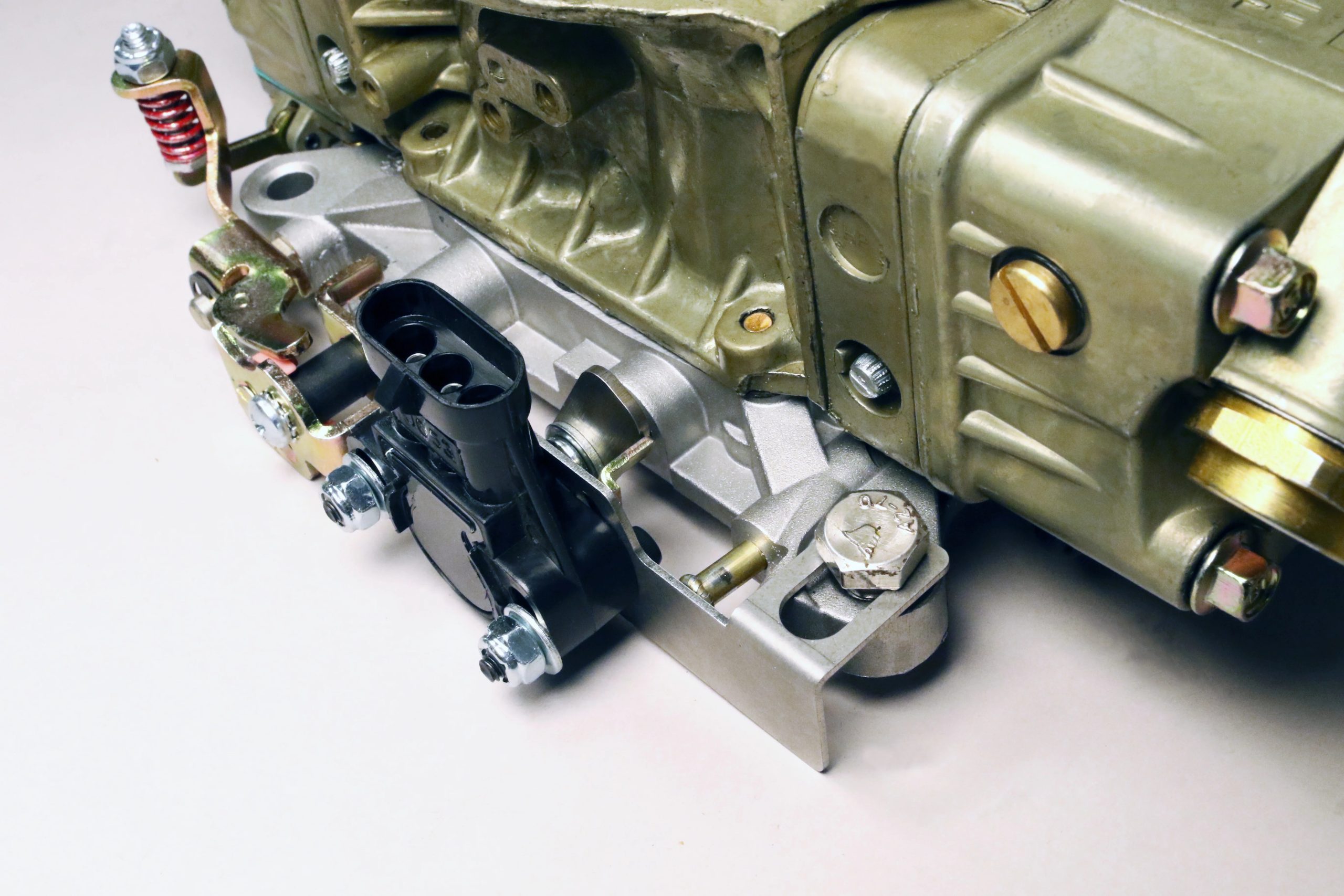

Next the boost controller solenoid and boost reference module are mounted. These need to ne mounted in a certain orientation to operate correctly. Vacuum lines are connected to each using a supplied T-fitting that comes in the kit. From there, a vacuum line is run to the wastegate. This will allow the gauge to control boost levels.

With the bulk of the plumbing in place, Mills turned his attention to mounting the gauge. He purchased a cluster bezel that accepts two gauges. This will put the SCG-1 gauge directly in Mill’s line of sight, making it easy to monitor boost and A/F ratio. The 2 1/16-inch gauge slips into the bezel and is secured on the backside. From here, it’s all about wiring.

Following the instruction in the kit, Mills runs the appropriate wires to the fuse panel, gauge, and sensors. The most difficult part is finding a spot to cut a hole in the firewall to run wires into the driver’s compartment. With all of the proper connections made, the last step is calibrating the wideband sensor. Innovate includes detailed instructions on the correct way to calibrate the sensor. It starts with powering the system up without the sensor plugged in. Once the system recognizes there is no sensor, it all gets powered down and the sensor is plugged in. With the sensor in open air, the system will power back up. After the sensor reaches its operating temperature, it will automatically go into calibration mode. Once this is complete, the system is powered down again and the sensor can be installed in the exhaust system. With everything reconnected, the SCG-1 is ready to go!

(Left) Mills then switches his attention to the required electrical connections. Each set of wires is labeled and prepared to be run into the driver’s compartment. Make sure to use the proper relay when installing the gauge system. (Right) Now it is time to calibrate the wideband sensor. Innovate gives you great step-by-step instruction on the calibration process. It also includes information on when and how often the sensor should be calibrated. This ensures the most accurate information over the life of the sensor.

This simple system has some incredible features that are extremely useful to anyone with a turbo application. Boost levels are able to be set right through the gauge or using Innovate’s software, and the gauge can be used with most data loggers. The gauge has its own datalogging capabilities when used with Innovate’s LogWorks software. The gauge is extremely user friendly and offers the perfect blend of data delivers with great fail-safe readiness.