We install an MTX-L PLUS, MTX-A Boost, and MTX-A EGT gauges on a 500 horsepower, SR20DET powered Nissan 240sx S14.

In the early years of automotive performance, the technology of the time proved a limiting factor. Carburetion and mechanically timed ignition systems served as the means by which fuel delivery and spark facilitated combustion within the cylinders. The advent of fuel injection, electronic ignition systems and computerized engine management systems not only improved engine performance, but also efficiency. As time marched forward, these systems also progressed, becoming faster and even more efficient.

Engineers also improved many aspects of the combustion engine to reduce weight and displacement while increasing output. Smaller displacement engines began generating horsepower and torque, which was once thought to be only possible in a large displacement engine. Higher compression ratios and forced induction proved to be effective performance strategies. However, these dramatic increases in performance demanded precision tolerance and calibration.

A good example of a high-output, small displacement engine can be found in this 1997 Nissan Silvia S14. The factory turbocharged SR20DET engine offers tremendous performance potential with the right bolt-on parts. In stock trim with a sport turbocharger, camshafts and the appropriate ancillary bolt-ons, 400-wheel horsepower was realized on 91 octane with water-methanol injection.

The Silvia was then upgraded with a 2.3-liter, bored and stroked SR20DET engine. The new block featured Dan Benson Signature cylinder sleeves, JE Pistons and TOMEI Powered connecting rods and stroker crankshaft.

The Silvia was then upgraded with a 2.3-liter, bored and stroked SR20DET engine. The new block featured Dan Benson Signature cylinder sleeves, JE Pistons and TOMEI Powered connecting rods and stroker crankshaft. Relying on a Garrett GTX3076R turbocharger for boost pressure, the enhanced engine put down 513-wheel horsepower to the rollers of a Dynojet 424xLC2 dynamometer with California’s abysmal 91 octane pump gas in the tank. Generating over 220 horsepower-per-liter at the wheels, this engine won’t last long if its engine management isn’t calibrated properly or if there is a failure in the fuel delivery. Monitoring air-to-fuel ratios becomes paramount.

Stoichiometric, Lean and Rich

In a combustion engine consuming gasoline, an air-to-fuel (A/F) ratio of 14.7:1 is necessary for complete combustion. This is known as stoichiometric (or stoich). Based on this standardized ratio, too much fuel (A/F ratios below 14.7:1) is recognized as a rich condition, though a richer air/fuel ratio number is normal under load. This can lead to wall wetting, where excessive quantities of fuel delivered to the cylinders rinses the engine oil from the cylinder walls. Other common issues that can arrise included fouled plugs, excessive carbon build up, and pre maturely fouling oxygen sensors.

This reduction of the lubrication layer accelerates wear on the cylinders and the rings, which will lead to blow by, accelerated oil consumption and reduced performance. Conversely, too much air results in a lean condition (A/F ratios greater than 14.7:1.) Running lean results in increased combustion chamber temperatures that could lead to pre-ignition or detonation. This mistimed combustion of the incoming air and fuel will inevitably lead to a blown engine.

Performance Air/Fuel Ratios

So, what is the ideal air/fuel ratio? Although 14.7:1 is the ideal ratio for gasoline at cruise and idle, the ideal target ratio changes based on the fuel and the type of engine you’re running. For example, 6.4:1 is stoichiometric for alcohol while 14.5:1 is ideal for diesel fuel. Another consideration is the cylinder pressure. If an engine is running high compression pistons or forced induction, elevated cylinder pressures and temperatures warrant a slightly richer fuel mixture to defend against detonation. When adjusting the fuel delivery and spark timing for engines under these conditions, many tuners elect to run a slightly richer air/fuel mixture to defend against detonation. So how do tuners ensure that they are hitting their target ratio? They rely on a wideband air/fuel gauge.

New at SEMA 2016

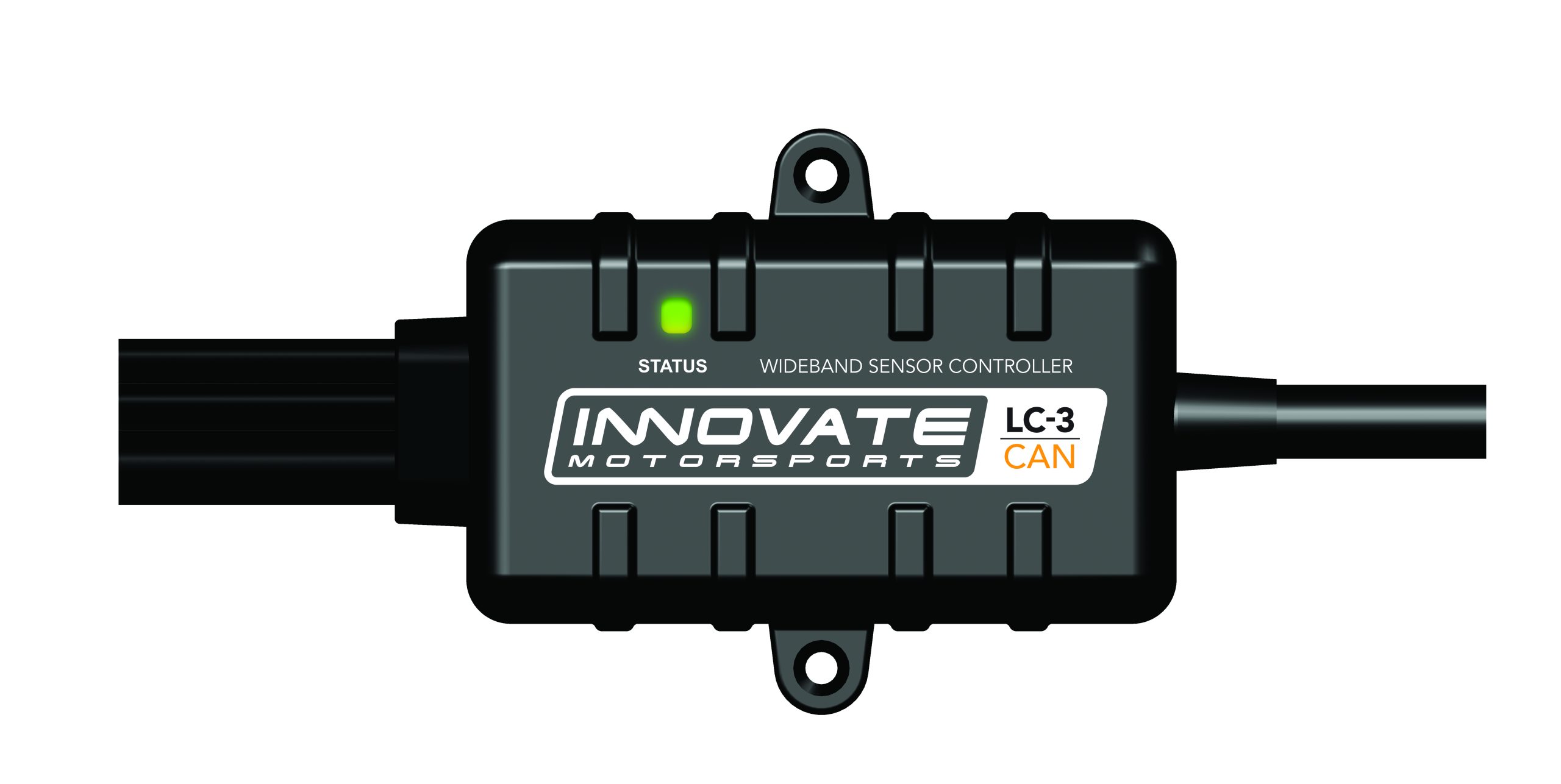

Innovate Motorsports has ridden the cutting edge of wideband air/fuel monitoring, dating back to its LM-1 unit in the early 2000s. Since then, the company has released smaller and faster gauge-type wideband air/fuel monitoring devices. The company’s latest development, the MTX-L PLUS wideband Air/Fuel gauge, made its debut at the 2016 SEMA Show in Las Vegas, Nevada. This is Innovate Motorsports’ fastest wideband air/fuel gauge yet.

Quick Thinking

Building upon the standard established by its previous best-seller, the MTX-L wideband air/fuel gauge, Innovate Motorsports improved its new digital MTX-L PLUS to be seven times faster than its predecessor with a faster analog output speed (4ms response time). It also features an increased sensor frequency for faster Lambda acquisition, improved heater control for superior sensor performance in rich conditions and optimal O2 sensor longevity. However, the MTX-L PLUS is only as fast as the sensor that is supplying it with information. Therefore, Innovate Motorsports includes the latest Bosch Wideband Oxygen Sensor, the LSU 4.9. This new sensor enables the MTX-L PLUS to sample the exhaust contents quickly and accurately, supporting most fuel types. Keep in mind, leaded and two-stroke fuels will shorten the oxygen sensor’s life.

Customized Display

The MTX-L PLUS kit includes two bezels and two gauge faces to allow up to four different color combinations to best complement your dash, gauge selection or instrument cluster. The gauge comes preprogrammed for unleaded fuel with an air/fuel range of 7.35:1-to-22.39:1. With a PC and the included serial port cable connected to the output cable, you can use Innovate Motorsports’ Logworks software to adjust the scale (lambda and air/fuel) for the analog output as well as adjust the scale of the red, yellow and green LED lights. As a member of Innovate Motorsports’ Modular Tuning System (MTS) product line, the MTX-L PLUS can function alone or be connected to any of the other MTS gauges for datalogging and programming purposes.

Functional and Practical

The MTX-L PLUS is not a mere fashion accessory. It’s a proper tuning tool that delivers useful data that keeps you informed of how your engine is performing and if there are any issues you should know about. This also goes for the condition of the gauge as well. A gauge is only as good or useful as it is accurate and functioning properly. The latest in DirectDigital Technology includes heater control to maintain the sensor and ensure optimal performance. This technology is also self-diagnosing, displaying an actual error message if there is a sensor failure or malfunction, rather than simply reading erroneously and causing confusion.

An EGT probe is designed to sit in the exhaust’s air stream to detect accurately monitor its temperature.

Hot or Not? – Innovate’s Analog EGT Gauge

Another calibration variable that can be monitored is exhaust gas temperature (EGT). The temperature of the exhaust gasses leaving the combustion chambers is a reliable indicator of the fuel mixture being combusted. What is the usual temperature? The ideal exhaust temperatures will depend on the fuel being consumed. For example, the optimal exhaust gas temperature range for unleaded fuel will differ from that of diesel fuel.

To monitor this variable, an Innovate Motorsports MTX-A EGT gauge was added in supplement of the MTX-L PLUS. Like the other gauges in the MTX series of gauges, the MTX-A (A for analog) EGT gauge features a 52mm diameter gauge capable of being linked to other gauges in the series and then logged by way of the Logworks software or the PL-1 Pocket Logger.

The EGT gauge is an ideal spot check for your engine’s fuel calibration. By placing the thermocouple probe in the header pipe of one cylinder, the exhaust leaving the combustion chamber can be measured and interpreted. If the temperatures are too hot, the fuel mixture is lean. If the temperatures are lower than usual, the mixture is rich.

If your application calls for even more specific monitoring of engine function, the Innovate Motorsports TC-4 PLUS (p/n 3915) monitors up to four thermocouples and interfaces with the MTS product line for monitoring and datalogging. This is ideal for monitoring each cylinder to ensure proper function and calibration of the fuel delivery and spark. Additional units can be added to accommodate any number of cylinders.

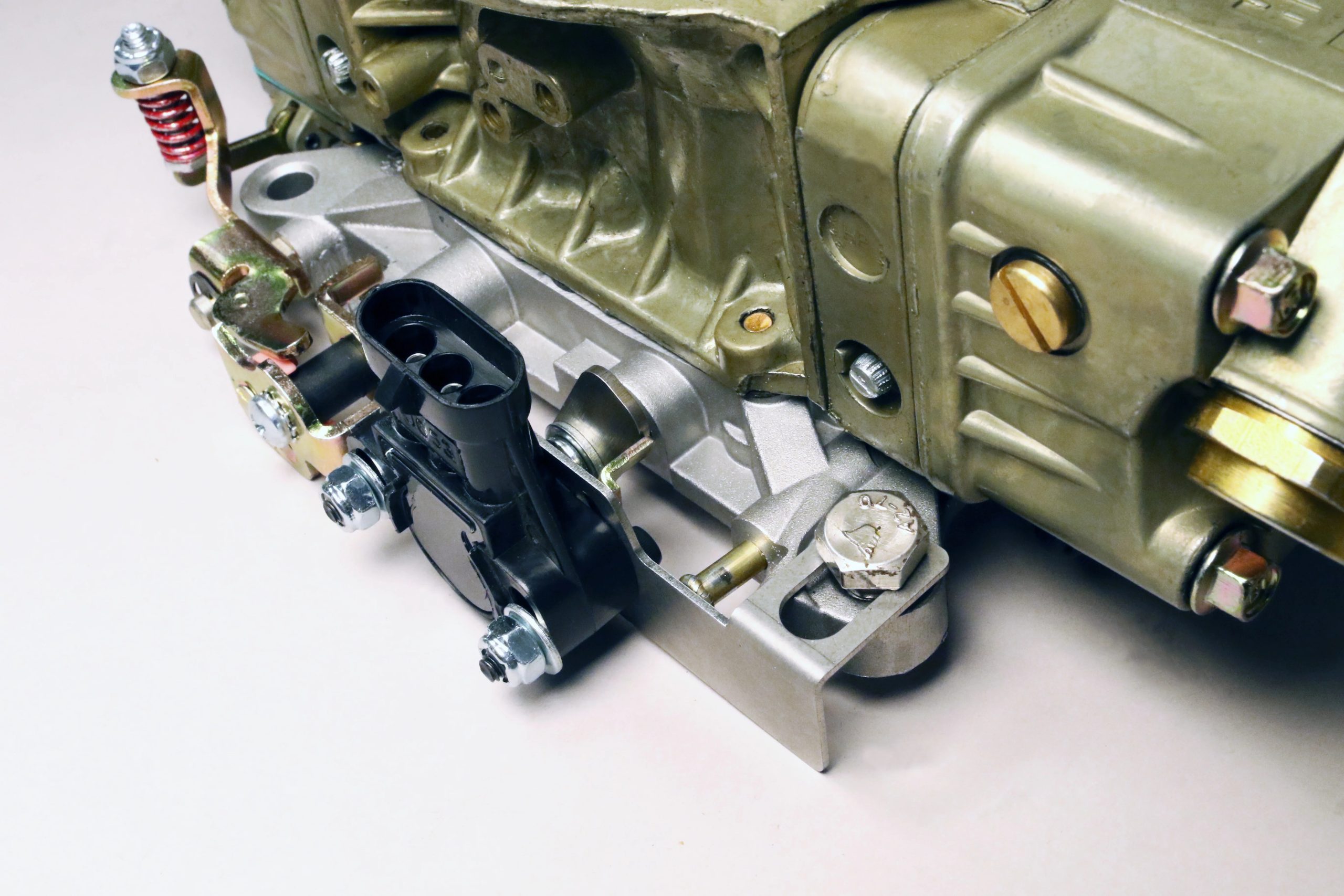

ay Attention to Pressure – Innovate’s Analog Boost Gauges

Critical engine vitals include a myriad of other variables, including boost pressure. Monitoring the boost pressure keeps you apprised of the volume of air being forced into the engine. Knowing that your engine is receiving the appropriate boost pressure is essential for optimal performance. It also informs you of proper wastegate function and calibration. If there is an issue with your forced induction system, a boost gauge can inform you of potential issues.

Innovate Motorsports’ MTX-A vacuum/boost gauge offers both monitoring and logging capabilities. Available as a 20 psi or a 30 psi gauge, the MTX-A vacuum/boost gauge can provide monitoring for a variety of applications. For this 2.3-liter SR20DET application, we elected to incorporate the 30 psi gauge since our horsepower targets required boost pressure targets between 23 psi and 26 psi. The serial input and output permits connectivity between the boost gauge and other MTX gauges.

So how does observing the boost pressure help with determining if there is an issue? Knowing that target boost pressures should fall between 23 psi and 26 psi, anything outside this range points to a variety of potential problems. For example, if boost fails to reach target pressures, it could be an indication of a boost leak, a wastegate problem or a boost control issue. On the other hand, if boost pressure exceeds the prescribed target, there could be a wastegate or boost control malfunction.

In the Know

Knowledge is power, and it’s imperative to know your engine’s vital signs to maintain output and reliability. With Innovate Motorsports as your data monitoring and collection partner, you’ll be informed and up to speed.

Part Part Number MSRP

MTX-L Plus Wideband UEGO 3918 $219

MTX-A EGT Gauge 3865 $249

MTX-A Vacuum/Boost Gauge, 30psi 3908 $219