Have a V-Type or boxer engine? Then you need to take a look at the DLG-1 gauge, which allows you to monitor the air-fuel ratio on both sides of your engine

Believe it or not, there was a time when racers relied on nothing more than idiot lights to know the running condition of their engines. Naturally, it didn’t take long for actual gauges to replace those simple lights, and that helped drivers monitor the basics like coolant temperature and oil pressure. Monitoring temperature and pressure in real time allowed drivers to run their engine harder without (as much) fear of engine damage due to low (or no) oil pressure or overheating.

As engines became more sophisticated, tuners and racers craved better information. Racers would do their best to report the readings from those simple analog gauges, but that wasn’t exactly efficient or reliable. Truly understanding how an engine was performing required air/fuel ratio data and the ability to record it. This need for a/f or Lambda feedback grew into a necessity in the late 1980s and early 1990s, especially for calibrators tuning factory and aftermarket EFI engines. Frankly, there is no other way to safely extract 600, 700, or over 1,000 horsepower and keep the engine alive without knowing the air/fuel ratio.

The need arose for not only pros, but for the average enthusiast to gather a/f data. And Innovate Motorsports took the lead, offering one of, if not the very first stand-alone digital air/fuel ratio meters, known as the LM-1. Many racers and performance enthusiasts came to rely on the LM-1 and anyone who used one, quickly learned the importance of the data they were gathering.

In the last decade the Southern California-based firm has continually introduced new products that set the standard in air/fuel ratio gauge and data-recording technology. One of the latest offerings is the awesome DLG-1 (Dual Lambda Gauge), designed as a smart-looking, affordable, compact and complete gauge package that allows you to read and record air/fuel ratio on each bank of your V-6, V-8, V-10 or really any V-style engine.

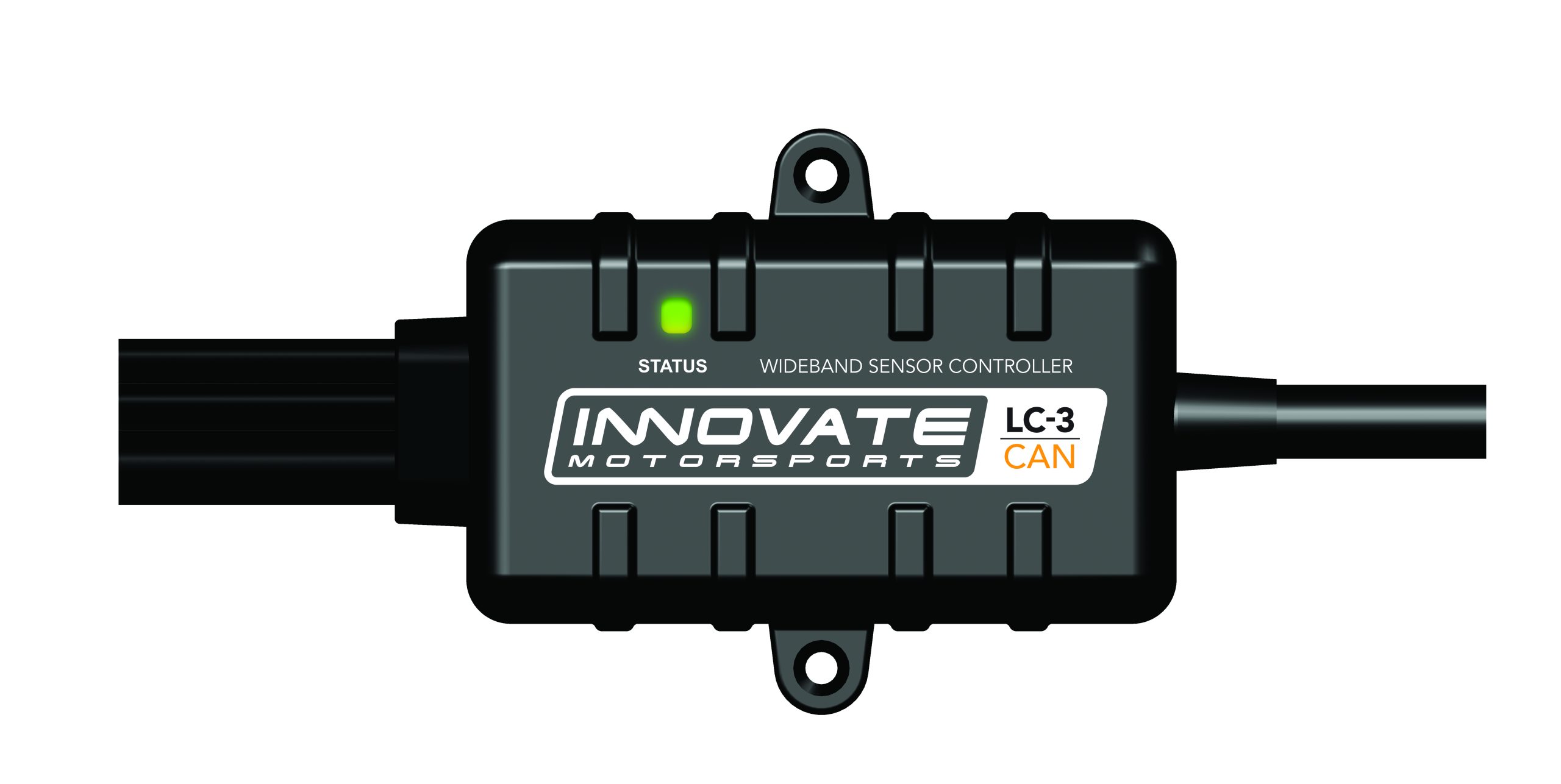

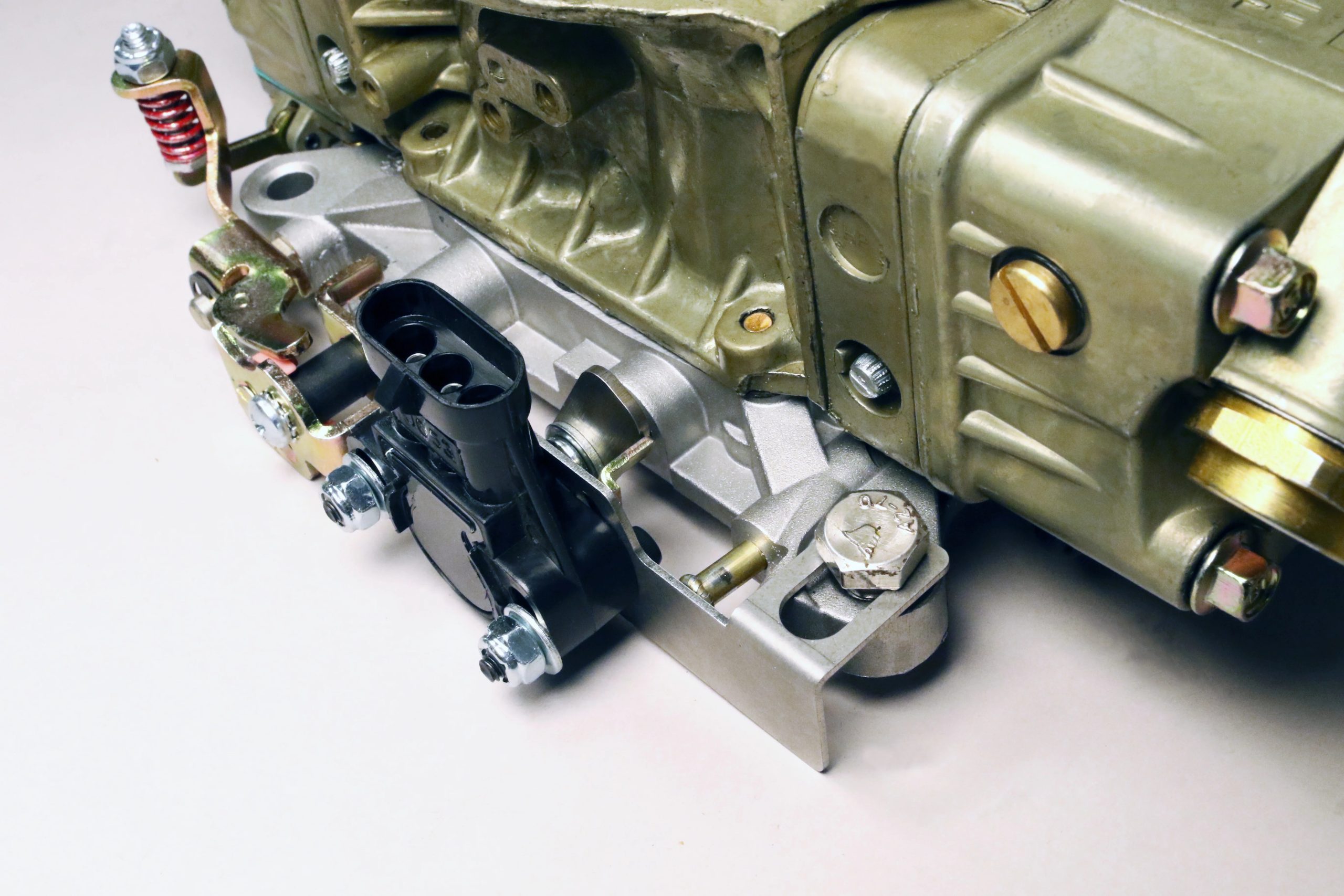

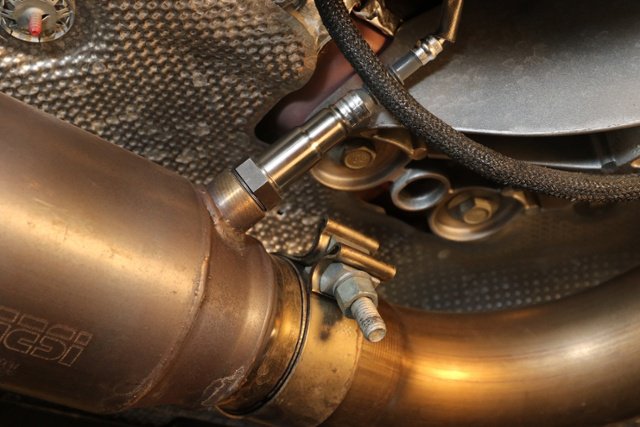

(Left) Innovate Motorsports DLG-1 kit comes with everything needed for a complete and easy installation. We recommend reading the instructions and then take your time to complete a clean, professional installation. Open the box and you’ll find two Bosch Wideband LSU 4.9 oxygen sensors, 8-foot sensor cables, LC-2 Wideband Controller, two weld-on sensor bungs, serial program cable, and the dual-readout gauge with two faceplates and black or silver bezel. (Center) Wiring the DLG-1 is straight forward. The red wire runs to an isolated switched 12V source in your vehicle, which goes “ON” with “key on” power. It’s also recommended that each connection is protected with a 5 amp fuse (not supplied). (Right) You’ll also find Innovate Motorsports’ LC-2 wide band controller as part of the kit. The gauge contains the wideband controller for one sensor and the LC-2 controls the second.

Accurately monitoring/recording air/fuel or Lambda is a key element in tuning—it’s especially important with the elevated cylinder pressures associated with a supercharger, turbo or nitrous combination. It’s not only important for reaching and maintaining peak power, but to alert you of excessively rich or lean conditions. The last thing you want it a burnt exhaust valve or ruined cats because your engine ran overly rich, or preventable catastrophic failure due to detonation. Actually, having accurate and reliable a/f data is critical no matter how much power your engine makes. Combining the DLG-1 with a little dyno tuning (chassis or engine), can unlock power and increase durability and economy.

The DLG-1 is affordable, relatively easy to install, and offers a long list of easy-to-use features. Each DLG-1 Lambda Air/Fuel Gauge kit includes a pair of Bosch Wideband LSU 4.9 oxygen sensors, 8-foot sensor cables, LC-2 Wideband Controller, two weld-on sensor bungs, serial program cable, and the dual-readout gauge with two faceplates and black or silver bezel. The DLG-1 can display a/f ratio of Lambda, neatly ties in left and right banks of the engine and is priced under $400.

The 12 volt switched wire for the relay was tapped off the coil harness. The relay’s power is connected directly to the fuse box power in the front left of the engine bay and mounted there as well.

And while the digital gauge is itself impressive, so is the LC-2 digital O2 sensor controller included in the kit. The LC-2 utilizes 100-percent digital wideband air/fuel ratio technology with DirectDigital signal processing technology that provides accurate readings no matter the engine load. The LC-2 is self-calibrating and compensates for varying weather and driving conditions, so it’s also perfect to pair with your dyno, aftermarket ECUs or data-logging equipment. It can also be used for individual cylinder monitoring.

The gauge itself is modern and was paired with an aftermarket suction-cup mounting system to fit conveniently in the interior of modern cars. And to ensure the perfect look, Innovate Motorsports includes interchangeable bezels and face-plates to let you customize the gauge to fit your vehicle.

Ultimately, though, what you love most is the cost (about $400), the ease of installation and the accuracy at which you’ll be able to monitor the single most critical element of your engine—the air/fuel ratio. This devise is perfect for the casual enthusiast to the seasoned professional racer looking to gather every drop of vital engine data.

To test out the system, we installed the DLG-1 on Cunningham Motorsport’s ProCharged6th gen Camaro.

DLG-1 Key Features

- Plug and Play setup for both O² sensors allows quick and accurate monitoring of both engine banks on V-style engines

- No PC required for additional configuration

- Gauge face measures 52mm (2 1/16-inch) diameter gauge body

- Choose between Black and Silver interchangeable faceplates. (Black and silver bezel, black and white faceplates included)

- Using the OLED screen, easily toggle between air/fuel or Lambda display

- Multiple ways to display data on gauge

- Patented DirectDigital wideband sensor control, which is the only 100-percent digital wideband air/fuel ratio technology today

- Wideband O² Compatible with leaded, unleaded, diesel, E85 and other fuels

- Ability to calibrate O² sensors for maximum accuracy

- Easily connect and configure linear 0-5v analog output for wideband O² for use with piggy back or stand-alone ECUs as well as external data loggers

- Innovate MTS serial in/out (for use with other Innovate and 3rd party MTS enabled devices to add additional logging channels)

- Ability to data-log both O² channels using powerful LogWorks software on your PC

The DLG-1 will display in either lambda or air/fuel ratio. In addition, there’s two variances in the gauge display configuation as pictured.